PCB with V-CUT design

V-CUT process comparison:

- Manual V-cutting Process

- Manual process, blades are exposed, there is a critical safety risk.

- The PCBA has no support at the bottom and is easy to deform

- Poor de-panel accuracy

- The cutting strain stress is un-controllable

- Low production efficiency and unstable capacity.

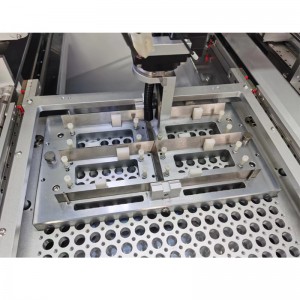

- Automatic In-line V-Cutting Process

- Automatic process, save labor, eliminate safety risks

- PC control & programable.

- The PCBA panel is supported by fixture to prevent deformation.

- CCD alignment, higher cutting accuracy

- Multi-stages of cutting depth controlling to minimize the strain stress

- 25% of UPH increasing.

- The cutting head can be rotated 270° to accommodate 0°, 90° v-cut groove design PCBA depaneling

- Built-in High- precision measurer for the blade wear compensation, ensure precision de-paneling.

- Multi-stages of cutting depth controlling to minimize the strain stress.

- Configured an industrial vacuum cleaner, effectively remove the dusts & particles.

- Configured CCD to realize automatic production, saves the manpower directly.

- It is with high efficiency, high precision, cost effective solution for inline de-paneling process for all kinds of PCB Panel with V-score line designs.

If you are interested in our products, please email to Sales@jinke-tech.com

| Name | Automatic In-Line V-CUT Machine |

| Model | JK-860R |

| Dimension | STD 300x300mmxT0.5-3.0mm,Customizable |

| Cutting Accuracy | +/-0.1mm |

| Cutting Speed | 0-400mm/s |

| Max. Strain Stress | ≤1000 με |

| V-score Line Angle | Horizontal 0° & Vertical 90° |

| Cutting depth | STD:Multi-stages control and Programmable |

| CCD Alignment | STD |

| Lifespan alarm of topside blade | STD |

| Automatic compensation for topside blade wearing | Option |

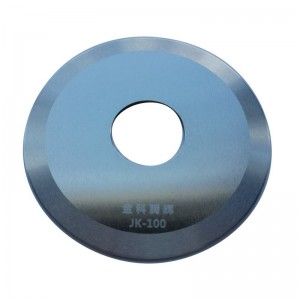

| Blade Brand | STD Made in China, Option CAB |

| Bottom Die Fabrication Service | Customized & Option |

| Waste Tabs Collection | STD,Waste Tabs size≥ 5 x 5mm |

| Bottom Vacuum Cleaning | Option |

| Process Direction | STD:L to R, Option:R to L |

| Conveyor Height | 950+/-50mm |

| Rail Width Control | PC Control |

| PCBA Output | STD: Belt, Option: Shuttle Carrier |

| SMEMA Port | STD, One on each side |

| Controlling system | Industrial PC+ PLC |

| Languages | Chinese/English |

| Operation system | WIN10 |

| Pass-word levels | 3 Levels, OP/ENG /Manager. |

| Color | White +JKTECH Blue |

| Power Supply | 1 Phase 220v 50/60 HZ |

| Connected Power | Main:~ 1kw, Cleaner: ~2.5Kw |

| Air Supply | 4~6kg/cm² |

| Foot-print | Approx. L1700mm×W1200mm×H1250mm |

| Net Weight | Approx. 750Kg |